Integrity Machine Services Equipment

IMS is your single source for filling and sealing applications. We offer expertise, commitment, equipment and services that keep your production up and running. Check out some of our equipment below.

With the smallest footprint of any IMS sealer, the MBT is perfect for lab operations. 120v power and 90 psi air consumption allows this product to seal multiple sized containers with one sealing head, or with electric actuator where air isn’t available.

These convenient machines are easy to troubleshoot, load and feel foil throughout the units. Tooling can be removed quickly for change outs and cleaning. Can also be designed with integrated conveyor or made to fit existing conveyor systems.

Our linear machines seal in one downward motion. This process is the fastest way to apply flat foil seals in the industry. Units can also be assembled on a walking beam for continuous feed motion, and provides the smallest footprint possible.

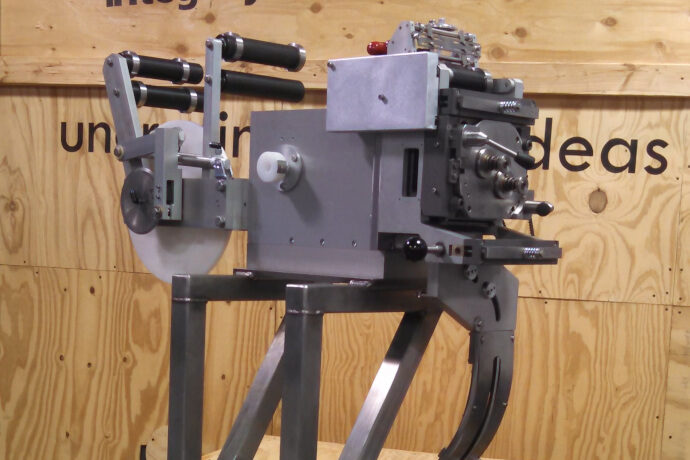

Skirted foil capping has been regarded as a cost effective, hermetic alternative to conventional screw capping. This application can provide a capless seal to your container with the option of adding an overcap. We have made it even better with the introduction of the Versa-Press foil capping system. We are confident that this system is the most mechanically versatile, cost efficient, skirted capping system on the market today.