How to Maintain Your Foil Press

Maintaining your foil press is essential to keeping your operations running smoothly. Although maintenance takes time, think of it like a regular health check-up—it’s critical for avoiding unexpected situations.

Now, every foil cap press is a bit different depending on who made it, so maintenance requirements will most likely be unique to each press.

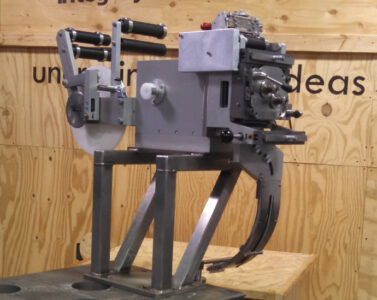

In this article, we’ll discuss how to maintain the foil press you purchase from Integrity Machine Services.

Foil Capping Press Maintenance

Daily

- Clean the collector and chute using alcohol or food-grade silicone on a soft cloth.

- Clean and lubricate the formers and pins using alcohol and a green scratch pad, followed by food-grade silicone on a soft cloth.

Weekly

- Clean all rollers with hot, soapy water or food-grade silicone and dry thoroughly. Do not use alcohol on poly loose feed and exit rollers.

- Clean the stripper using alcohol and a soft cloth.

Quarterly

- Check the oil level in the sight glass. The ideal level is at the center of the sight glass.

- Grease the six fittings on the feed and exit roller assembly, ensuring proper bearings are in use.

- Lubricate the rollers on the reel control. Use light oil on foil guide rollers.

- Clean ejectors and lubricate pins using alcohol or food-grade silicone on a small brush or cotton swab.

- Pull out the tool unit and clean it thoroughly using alcohol or food-grade silicone on a soft cloth.

- Check the air filter located in the base with the main drive and replace it if it’s dirty.

Remember—keeping your machine clean and free of buildup is key. Additionally, having the correct air settings and tracking adjustments are crucial to ensure optimal performance.

Troubleshooting Common Issues

You shouldn’t experience too many issues if you properly maintain your press. However, if you’ve noticed jamming, tracking issues, or problems making caps, follow our troubleshooting table below, and please always clean the machine thoroughly first before you make any adjustments:

| Problem | Possible Cause | Action |

| Tool Unit Jams | Unknown |

Before identifying possible causes, run the press with the collector down to see if that resolves the issue

|

| Tool Unit Jams | Ejection |

Check for 3/8 on the right and 7/16 on the left

|

| Tool Unit Jams | Air tube is out of position |

Set the air tube in front of the punch

|

| Tool Unit Jams | Air pressure is too high or low |

Check gauges and adjust the air pressure if needed

|

| Tool Unit Jams | Dirty formers |

Remove formers from the press and clean them with alcohol or food-grade silicone

|

| Tool Unit Jams | The stripper is dirty |

Clean the stripper with alcohol and food-grade silicone

|

| Tool Unit Jams | Ejector pins are dirty |

Clean the ejector pins with alcohol and food-grade silicone

|

| Tool Unit Jams | Ejector is dirty |

Clean the ejector with alcohol and food-grade silicone

|

| Tool Unit Jams | The embossing pad is sticky |

Clean with hot water

|

| Tool Unit Jams | The connecting link is loose |

Check the connecting bolt and tighten it if needed

|

| Tool Unit Jams | Foil tracking |

Check the foil alignment back to front

|

| Tool Unit Jams | Foil feed |

Check foil feed timing

|

| Tool Unit Jams | Belts are slipping |

Remove guards and check tension

|

| Tool Unit Jams | Broken ejector spring |

Inspect for broken spring

|

| Tool Unit Jams | Broken former spring |

Inspect for broken spring

|

| Tool Unit Jams | Moisture in air |

Check filters and replace the, if needed

|

| Collector Jams | Damaged caps |

Inspect caps for roundness

|

| Collector Jams | Stripper to collector misalignment |

Check alignment with collector up and realign if needed

|

| Collector Jams | Dirty collector |

Clean collector with alcohol and food-grade silicone

|

| Collector Jams | Air jets out of alignment |

Align air jets with caps

|

| Collector Jams | Air pressure leaks |

Check air pressure gauges and hoses

|

| Collector Jams | Collector to chute misalignment |

Check alignment and realign if needed

|

| Collector Jams | “Baseball caps” | Realign formers |

| Collector Jams | Damaged caps |

Check the caps before they get to the collector

|

| Press Jams | Rollers slipping |

Check rollers and clean them with hot, soapy water or food-grade silicone

|

| Press Jams | Tracking |

Check foil tracking front to back

|

| Press Jams | Tension on rollers is too loose or tight |

Check for proper tension

|

| Press Jams | Worn gears |

Check roller gears and replace them needed

|

| Press Jams | Too much or too little brake |

Check brake tension

|

| Press Jams | Ejection on caps | Check ejection |

| Press Jams | Air pressure is too low or high |

Check gauges and airlines

|

| Tracking Problems | Bad foil |

Try a different roll of foil

|

| Tracking Problems | Reel control (brake is too tight or loose, rollers are too tight or loose, reel to stripper is out of alignment, or the felt pads are too tight) |

Adjust tension on brakes and rollers, check for alignment of foil, and inspect and adjust felt pads if needed

|

| Press Won’t Stop Making Caps | Clutch dog problems |

Inspect clutch dog spring and cylinder and replace if needed

|

| Press Won’t Stop Making Caps | Bad sensor |

Check clutch sensor and replace if needed

|

| Press Won’t Stop Making Caps | Clutch solenoid |

Check and replace if needed

|

| Press Won’t Make Caps | Dirty proximity eye |

Clean eye with a soft cloth

|

| Press Won’t Make Caps | Dirty reflectors |

Clean reflectors with a soft cloth

|

| Press Won’t Make Caps | Air is low on the clutch |

Check the air pressure to the press and adjust if needed

|

| Press Won’t Make Caps | Clutch dog is stuck |

Inspect the clutch dog through the side cover and fix it if needed

|

| Press Won’t Make Caps | Clutch dog solenoid |

Check and replace if needed

|

| Chute Jams | Air pressure is too high or low |

Adjust the air regulator

|

| Chute Jams | Chute is out of alignment |

Check the chute where sections join together and realign if needed

|

| Chute Jams | Chute is dirty |

Clean using alcohol or food-grade silicone on a soft cloth

|

| Chute Jams | Bent rails |

Inspect rails and rail alignment

|

| Chute Jams | Damaged lids |

Inspect lid conditions

|

| Chute Jams | Bad foil |

Try a different foil roll

|

| Chute Jams | Air on rails |

Check and adjust

|

| Chute Jams | Air leaks |

Check hoses for leaks

|

| Lidding Problems | Bent lids |

Inspect for the source of damage

|

| Lidding Problems | Bad caps | Inspect caps |

| Lidding Problems | Cap applier out of alignment |

Check height and side-to-side alignment

|

| Lidding Problems | Dirty air jets |

Clean air jets using compressed air

|

| Lidding Problems | Air pressure is too high or low |

Adjust the air regulator

|

When to Call for Repairs

- The press won’t make caps, even after cleaning and inspecting

- Frequent jamming

- Pressure irregularities

- Poor foil quality (tears, wrinkles, inadequate sealing)

- Incorrect calibration

- Replacement components are needed

- You can’t locate the source of the damage

Get the Support You Need From IMS

Our team at IMS is here to help you prevent unnecessary downtime. When you purchase our Foil Cap Press, we’ll provide in-depth training and documentation on operation, maintenance, calibration, and troubleshooting. We even offer long-term service support!

Please contact us today if you have maintenance questions or need to schedule repairs.