Heat Sealing for Medical and Pharmaceutical Products

The medical and pharmaceutical packaging industry has undergone significant transformations over the past decade, with heat sealing emerging as a pivotal technology. This article covers how heat sealing, particularly through automated machines, aligns with the standards set by the FDA and enhances the quality and efficiency of packaging in the healthcare sector.

The Evolution of Packaging Standards in Healthcare

The Food and Drug Administration (FDA) maintains exceptionally high standards for medical and pharmaceutical packaging. This scrutiny has directed the spotlight onto the technologies used in sealing processes, ensuring they meet rigorous health and safety benchmarks.

Automated Heat Sealing Machines: Enhancing Quality and Efficiency

The introduction of automated sealing machines has been a game-changer in the medical and pharmaceutical industries. This leap in technology has enabled companies to scale up production while adhering to high-quality assurance standards. Here are three key benefits of this automation:

-

Reduced Human Error: Advanced automation technology has significantly minimized the risk of human error. Operators now have more precise control over the process, leading to fewer changeovers and a more streamlined, error-free production line.

-

Increased Production Uptime: These machines have greatly reduced downtime in the manufacturing environment, thereby boosting overall efficiency.

-

Improved Sealing Quality: The incidence of improperly sealed products has dropped substantially due to the precision and reliability of automated sealing machines.

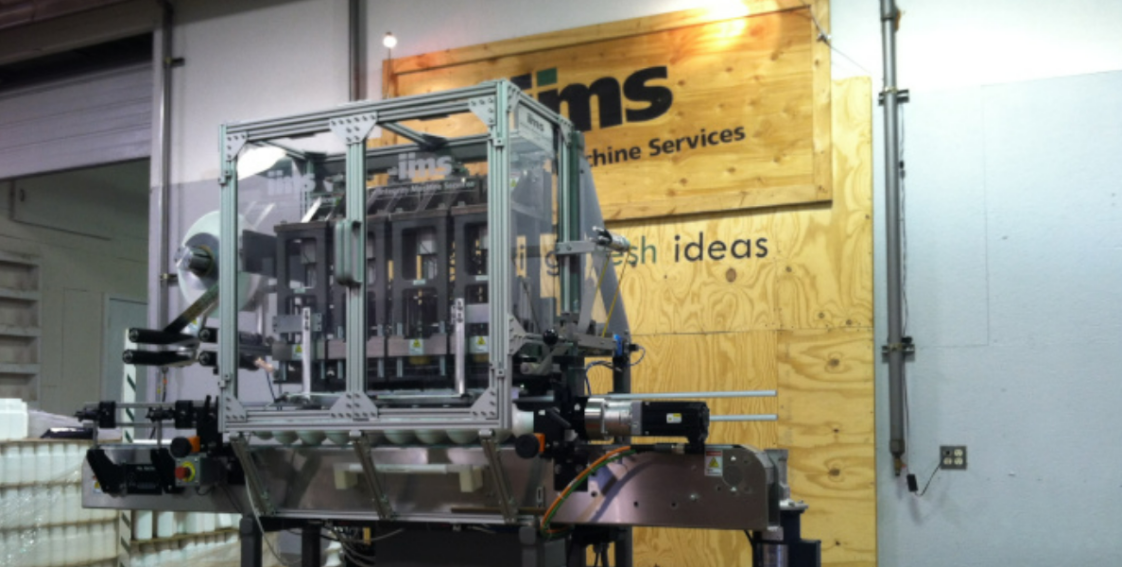

Visual Demonstration

This video showcases the capabilities of an IMS Inline Sealer, illustrating how it can seamlessly integrate into and optimize your manufacturing process.

Conclusion

The advancements in heat-sealing technology, particularly in the automation of heat-sealing machines, have brought about a revolution in medical and pharmaceutical packaging. This progress not only meets the standards of the FDA but also paves the way for more efficient, error-free manufacturing processes, ensuring safer and more reliable packaging for healthcare products.