SMAD: “Synchronous Motion Assembly”

Wouldn’t it be great if, as human beings, we had the capacity to perform multiple, intricate tasks simultaneously? Think of what you could accomplish in your daily life. Although many claim to be proficient in this area, multitasking is a skill that is seldom mastered. In manufacturing, the theory of multitasking manifests itself in the assembly line. Pioneered by Henry Ford in the early 1900’s, the concept is rather simple; instead of one team building an entire assembly from start to finish, each team performs a small, but unique, task as the assembly moves through the plant until the completed product rolls off the end of the line. This proven model of efficiency has changed the way products have been built ever since.

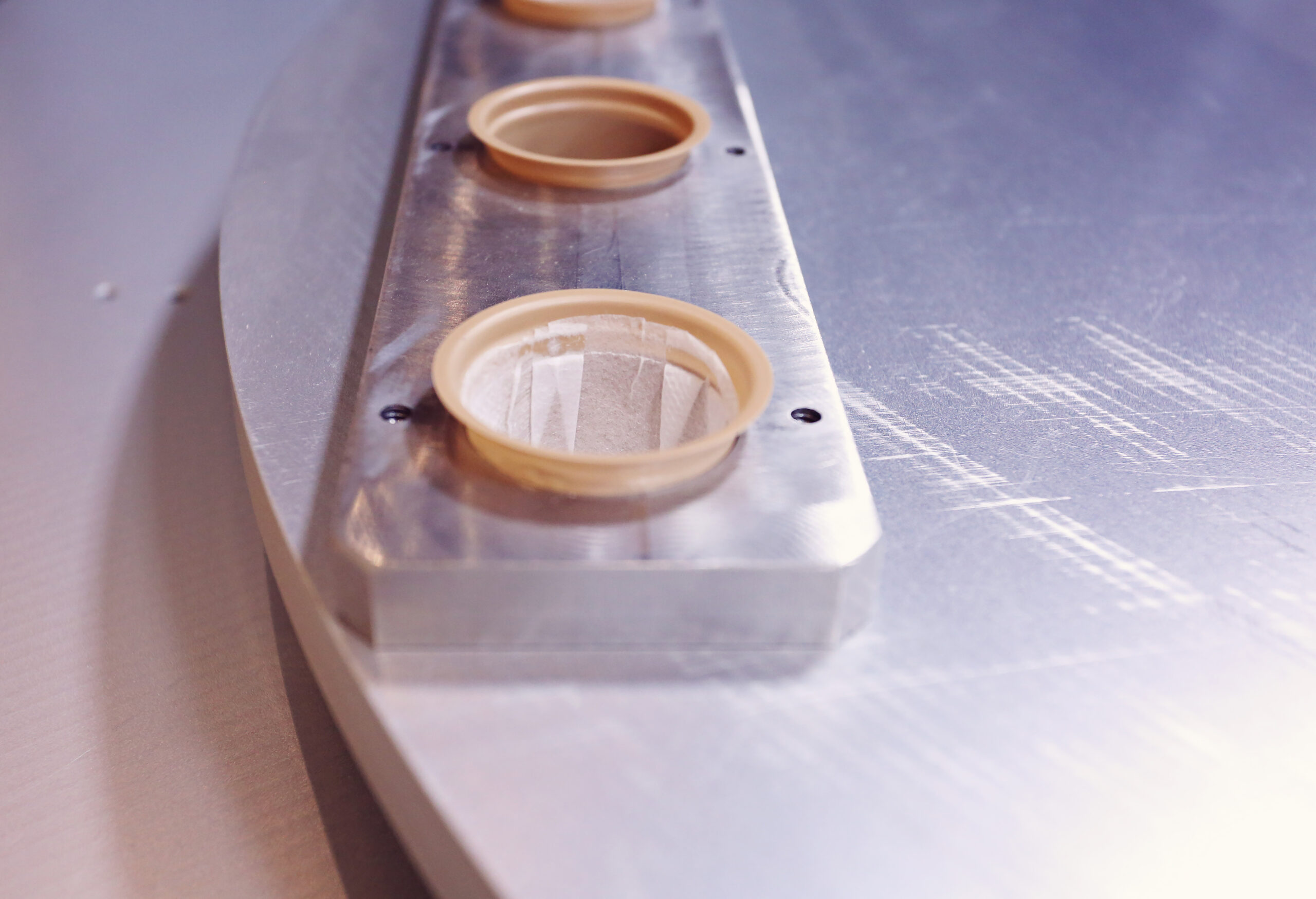

In small scale manufacturing, the assembly line process is often mimicked using some type of indexing apparatus; most commonly, a rotary dial for its accuracy and efficient use of floor space. As the dial indexes, a different assembly function takes place at each station. When the assembly exits the final station, it is removed from the machine as a finished product.

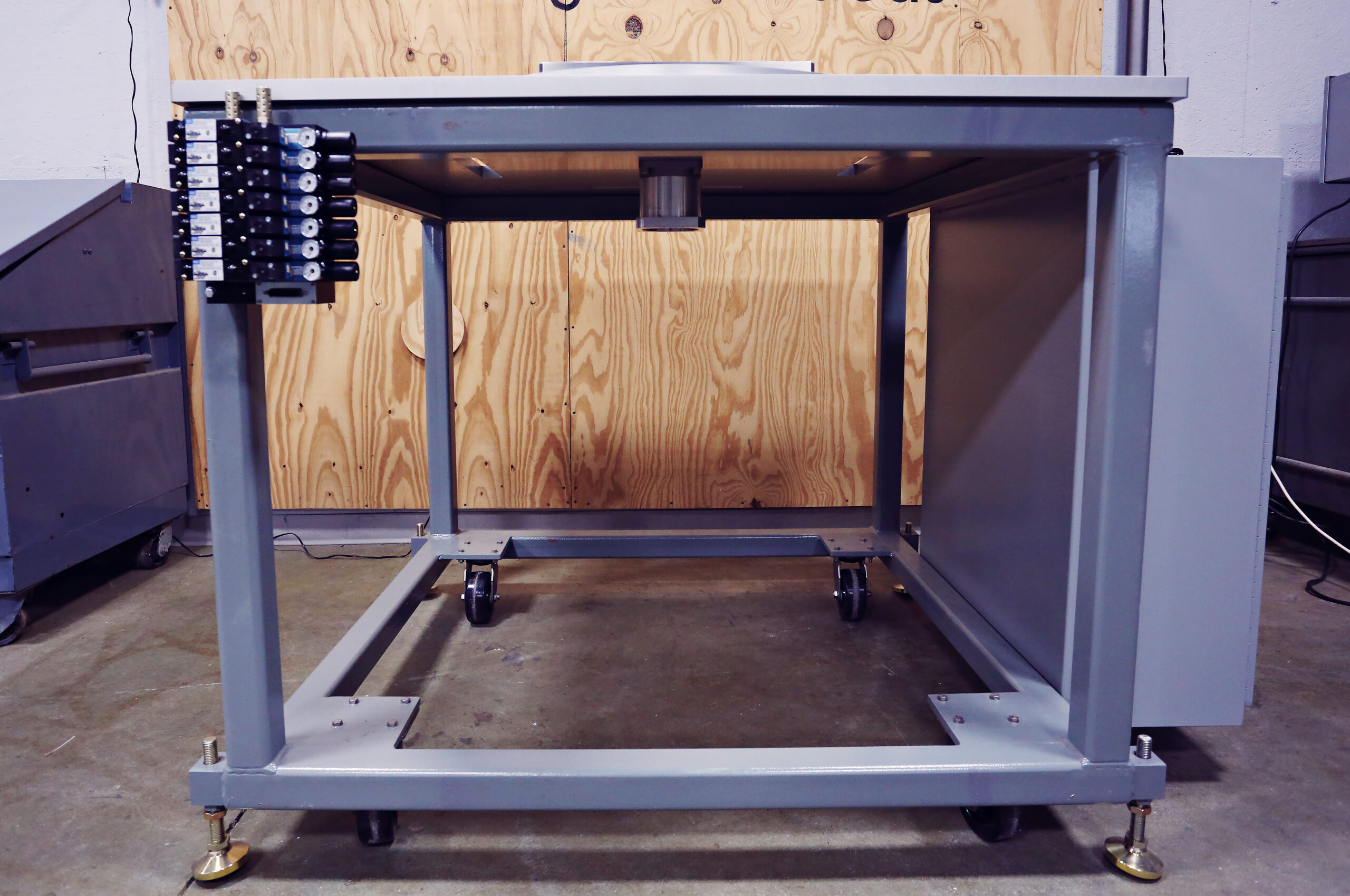

At IMS, a large percentage of our commissioned machine builds incorporate servo driven indexing dials as the foundation. We refer to these systems as SMAD (Synchronous Motion Assembly Dial).

Not only do we use SMAD systems in our own builds, but we also offer these systems to integrators, OEM’s and consumers to use as the foundation for their own designs.

Our standard dial sizes are 18”, 24” 36” and 48”, with limitless options for finishes and mounting configurations. Let us help you improve your operational efficiency, one index at a time.